Blacknip

Light absorption

Black, conductive, corrosion-resistant coating

general

BlackNiP is an electroless nickel deposit with a high phosphorus content. This gives it excellent corrosion resistance.

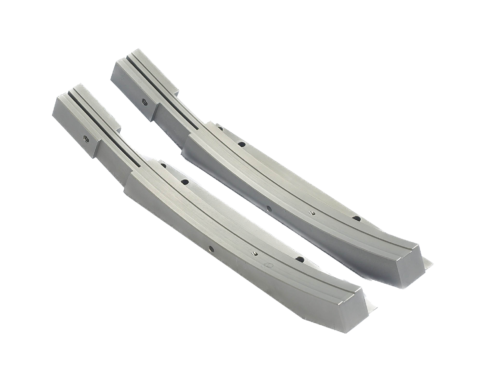

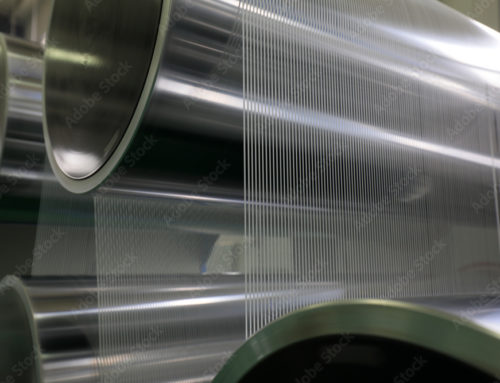

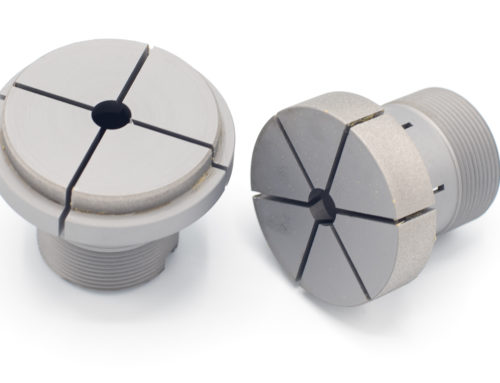

This deposit is used in applications such as light trapping in optics, or is applied to heat sinks that have to dissipate heat in extreme environments, or to complex, toleranced parts.

features

A micro-roughness is created on the surface of the deposit to trap light and render the deposit matt black. As a result, the electrical conductivity characteristics of electroless nickel are maintained. The thickness of the deposit is also homogeneous at all points on the part, and can be guaranteed with a very good tolerance.

technical properties

|

Functions |

Black, conductive and corrosion-resistant |

|

Vickers hardness of the deposit without chemical treatment |

550-650 HV 0.1 |

|

Vickers hardness of the deposit after 5h heat treatment at 200° C |

850-950 HV 0.1 |

|

Typical deposit thickness |

15 µm ± |

|

Deposit thickness tolerance |

5 µm ± |

|

Phosphorus content of NIP matrix |

9-12% Weight |

|

Special properties |

UV-resistant. Good UV absorption and IR emissions. |

|

NIP matrix melting point |

875 to 890°C (pure nickel : 1455°C) |

|

Operating temperature |

-197° to 400°C |

|

Deposit density |

7g/cm3 |

|

Adhesion to steel |

30 to 60 Kpsi |

|

|

0.7% |

|

Deposit color |

Black |

|

Bath capacity |

380x430x450mm |