SICANIP

Ceramic-reinforced composite

General

SICANIP composite coatings drastically improve the following features of your parts:

- Extreme abrasion resistance

- Hardness over 1000HV 0.1

Features

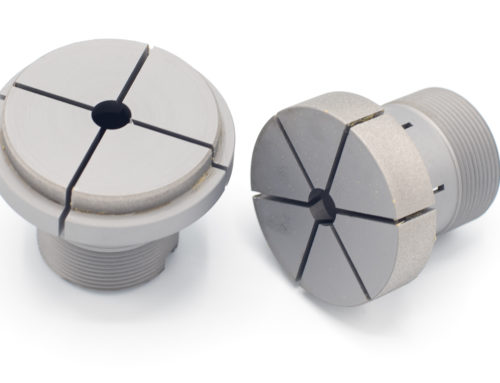

SICANIP deposits are part of composite materials. They are formed by immersing a part to be coated in a chemical nickel plating bath containing fine silicon carbide particles held in suspension by agitation. SICANIP consists of a tough nickel-phosphorus alloy matrix embedded with fine particles of silicon carbide (SiC). The addition of hard SiC particles (2500 HV) to the deposit makes it extremely resistant to abrasion and friction.

The final hardness of the coating results not only from the chemical bonds formed between the silicon carbide particles and the electroless nickel matrix during heat treatment, but also from the structural hardening of the nickel-phosphorus matrix.

The SICANIP coating is slightly abrasive in its unprocessed state. This often requires the machine operator to run in the deposit. To avoid this running-in phase, we can coat SICANIP with a thin layer of LUBRINIP BN, which has a very low coefficient of friction, guaranteeing immediate use at full speed without running-in.

Technical data

| SICANIP | |

|---|---|

| Functions |

Wear resistance hardness

|

| Particle type |

Green silicon carbide

|

| Grain size (median) |

3 – 5 µm

|

| Particle volume fraction | 20 – 30% |

| Hardness of PIN matrix |

600 – 800 HV 0.1

|

| Particle hardness |

23 GPa

|

| Coating hardness after heat treatment | 1100 HV 0.1 |

| Typical thickness |

20 µm

|

| Coefficient of friction(µd) | 0.15 – 0.3 |

| Melting point |

875 to 890 °C

(pure nickel: 1455 °C ) |

| Max. operating temperature |

Up to 300°C

|

| Adhesion on steel (S235) |

30 to 60 Kpsi

|

|

Coating ductility

|

0.5 – 1 %

|

| Color |

Grey (mat) with a light green touch

|

| Tank size |

800 X 400 x 500 mm

|