Dianip C

Increased coefficient of friction

General

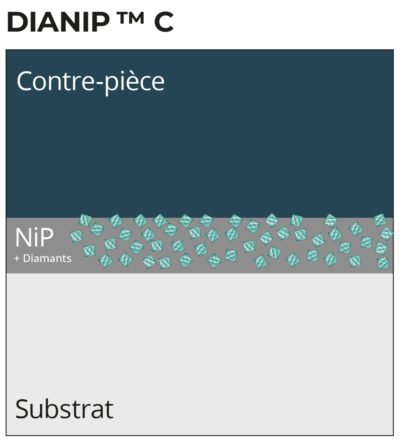

DIANIP C is an abrasion-, wear- and friction-resistant coating. The coating is composed of an electroless nickel matrix incorporating fine diamond particles, giving it exceptional tribological properties.

This fine diamond powder, about 2 microns in size, is used to protect mechanical parts subject to high levels of abrasion and friction. Thanks to homogeneous incorporation throughout the thickness of the deposit, the properties of the treatment are retained over time.

Features

DIANIP coatings are composed of DIAMOND single crystals embedded in a CHEMICAL NICKEL matrix. The properties and usefulness of DIANIP coatings depend essentially on the size of the diamond single crystals incorporated.

The perfectly defined size of the embedded diamond single crystals produces surfaces with absolutely even, defined roughness. Co-deposition and coating are carried out chemically, enabling coatings of perfectly even thickness to be produced, without edge effects, and diamond to be co-deposited at any point on a surface, even a complex surface with small internal diameters, provided they are continuous.

Technical data

| Property | DIANIP C2 | DIANIP G10 | DIANIP G13 | DIANIP G25 | DIANIP G35 | DIANIP G50 |

|---|---|---|---|---|---|---|

| Functions |

Abrasion, wear and friction resistance

|

Roughness, Grip, Training | Roughness, Grip, Training | Roughness, Grip, Training | Sharpening | Sharpening |

| Particle type |

Single-crystal diamond

|

Single-crystal diamond | Single-crystal diamond | Single-crystal diamond | Single-crystal diamond | Single-crystal diamond |

| Grain size (median) |

2 µm

|

10 µm

|

13 µm

|

25 µm

|

35 µm

|

50 µm |

| Fill-factor | N/A |

8 – 55%

|

8 – 55% | 8 – 55% | 8 – 55% | 8 – 55% |

| Hardness of PIN matrix |

400 – 600 HV 0.1

|

400 – 600 HV 0.1 | 400 – 600 HV 0.1 | 400 – 600 HV 0.1 | 400 – 600 HV 0.1 | 400 – 600 HV 0.1 |

| PIN matrix thickness |

from 3 to 80 µm

|

from 6 to 12 µm

|

from 8 to 12 µm | from 15 to 19 µm | from 9 to 27 µm | from 28 to 36 µm |

| Total thicknessof DIANIP coating | idem |

15μm ± 10μm

|

17.5μm ± 10μm | 30μm ± 10μm | 45μm ± 15μm | 65μm ± 25μm |

| Bath capacity |

980 x 630 x 1000 mm

|

400 x 400 x 500 mm

|

400 x 400 x 500 mm | 400 x 400 x 500 mm | 800 x 400 x 500 mm | 800 x 400 x 500 mm |

| Coefficient of friction(µsvs. steel) | 0.4 – 0.6 | 0.55 – 0.80 | 0.55 – 0.80 | 0.55 – 0.80 | 0.55 – 0.80 | 0.55 – 0.80 |

| Melting point |

875 to 890 °C (pure nickel: 1455 °C )

|

875 to 890 °C (pure nickel: 1455 °C ) | 875 to 890 °C (pure nickel: 1455 °C ) | 875 to 890 °C (pure nickel: 1455 °C ) | 875 to 890 °C (pure nickel: 1455 °C ) | 875 to 890 °C (pure nickel: 1455 °C ) |

| Melting temperature |

Up to 300°C

|

Up to 300°C

|

Up to 300°C

|

Up to 300°C

|

Up to 300°C

|

Up to 300°C

|

| Adhesion to steel |

30 to 60 Kpsi

|

30 to 60 Kpsi | 30 to 60 Kpsi | 30 to 60 Kpsi | 30 to 60 Kpsi | 30 to 60 Kpsi |

|

Elasticity (uncured deposit)

|

0.7%

|

0.7%

|

0.7%

|

0.7%

|

0.7%

|

0.7%

|