Lubrinip PTFE

Non-stick electroless nickel composite deposit

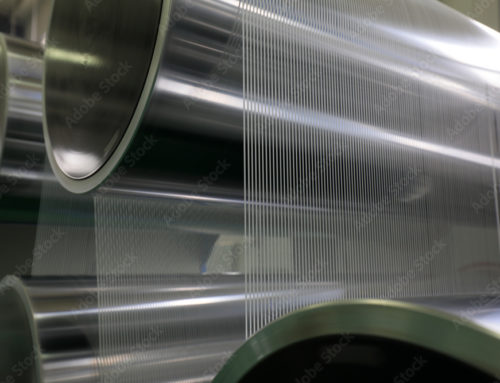

Homogeneous incorporation of PTFE into the matrix

General

Lubrinip PTFE is a composite deposit consisting of a nickel-phosphorus alloy matrix in which very fine particles of PTFE (Teflon) are incorporated, giving the surface non-stick and sliding properties. Thanks to the homogeneous incorporation of PTFE throughout the thickness of the deposit, these properties are constant and regenerative.

Lubrinip PTFE is a composite deposit consisting of a nickel-phosphorus alloy matrix in which very fine particles of PTFE (Teflon) are incorporated, giving the surface non-stick and sliding properties. Thanks to the homogeneous incorporation of PTFE throughout the thickness of the deposit, these properties are constant and regenerative.

Lubrinip PTFE coating is particularly recommended when a non-stick, hydrophobic surface is required that reduces the coefficient of friction/friction. This reduces wear and tear on mechanical parts and the associated maintenance costs. Its hydrophobic nature provides cost-effective solutions to lubrication, friction, adhesion, wear and corrosion problems.

Our Lubrinip PTE treatment can be applied with excellent adhesion to all common metals and construction alloys, as well as light aluminum and magnesium alloys.

Features

| Type of deposit | Functions | Tank capacity |

|---|---|---|

| NiP + PTFE | Anti-adhesion, slip | 1490 x 480 x 900 mm |

Lubrinip PTFE treatment is a chemically deposited nickel dispersion layer. This indicates that a uniformly distributed incorporation of tiny non-metallic particles (PTFE) is present in the nickel-phosphorus matrix. Offering the following benefits in particular:

Depending on the temperature and duration of the treatment, a post-surgical heat treatment of the treated parts can modify certain aspects of the product.

deposit properties, such as; improving lʼadhesion, relaxing internal stresses and increasing hardness, toughness or ductility.

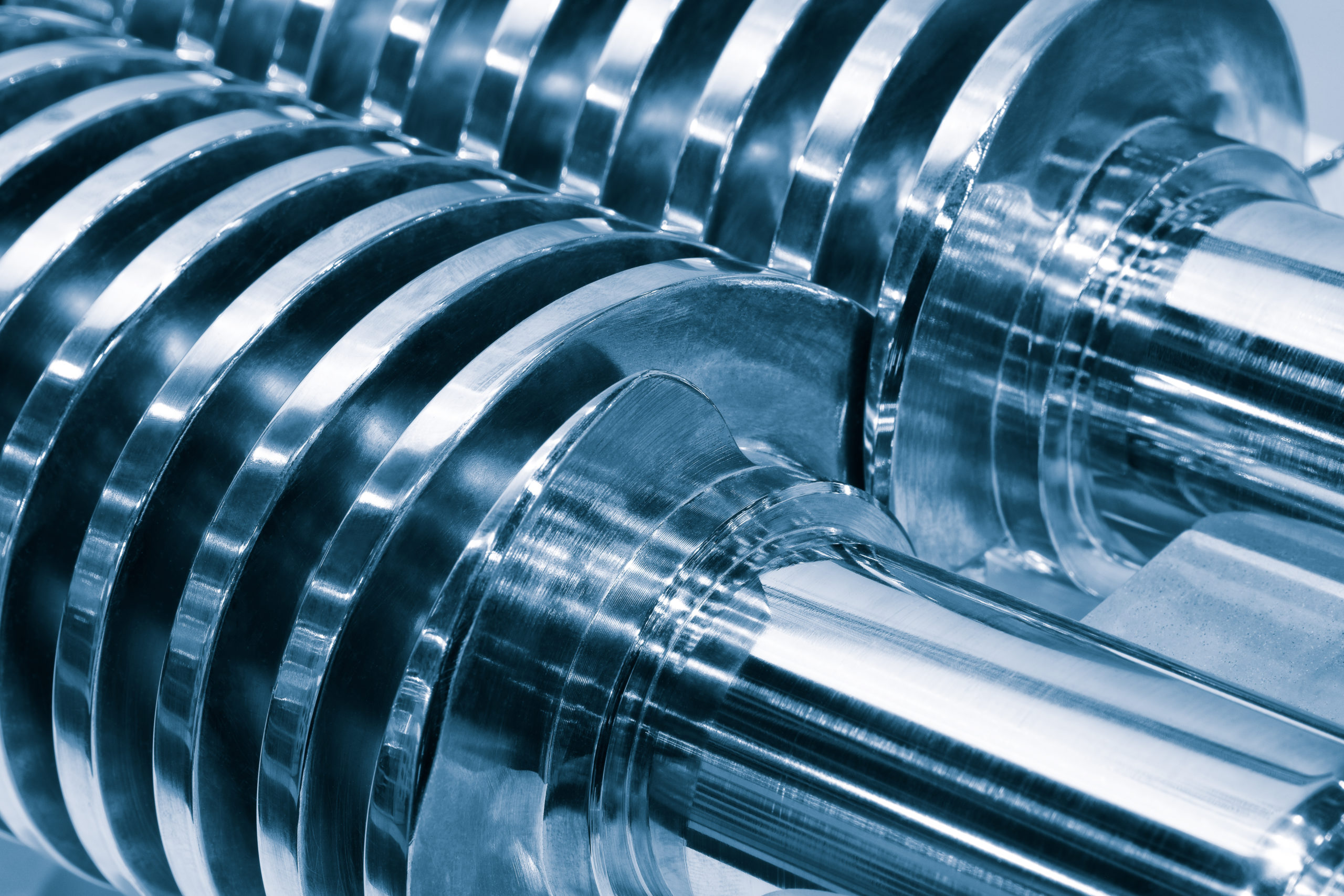

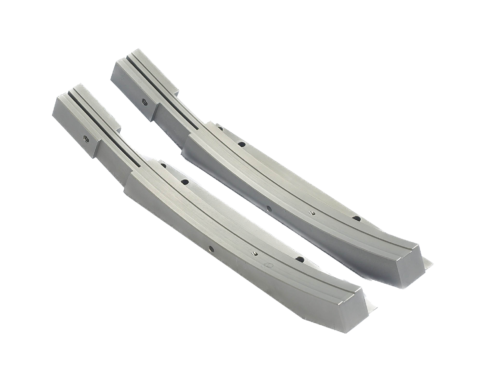

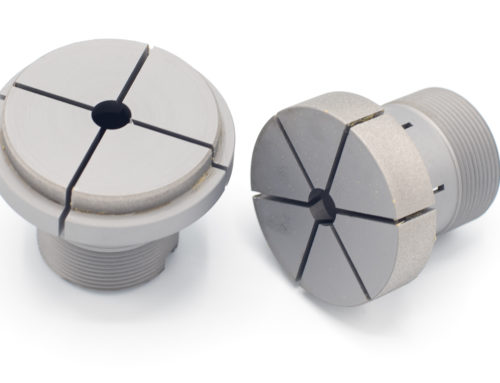

Application examples

Physical properties

| Chemical composition | Phosphorus | Nickel 9 – 11% Weight | 89 – 91 % Matrix weight |

| PTFE Ø PTFE particles |

approx. 25% Volume < 1µm |

Embedded particles | |

| Hardness | 350 HV non-heat-treated. | ||

| 550 HV after heat treatment (290°C, 5 hours) | |||

| Friction coefficient | ~ 0.1 against polished steel surface. | ||

| Deposit thickness | 5 to 10µm recommended. For thicker deposits, we recommend increasing the thickness of the pure electroless nickel undercoat. | ||

| Magnetism | Slightly magnetic | ||

| Operating temperature | Up to 350°C, briefly up to 600°C. | ||